Interview of Kosuke Hirabayashi from Hirabayashi Design Studio

.png)

Hirabayashi Design Studio has recently created a 3D Printed guitar, we had the chance to have Mr.Hirabayashi over at Shade3D's office. He will tell us more about this amazing 3D Printed electric guitar...

Shade3D: (Looking at the instrument) Awesome concept guitar! Tell us about the 3D Printed part.

K.Hirabayashi: The neck hasn't been 3D printed, we used maple. The body is another story though, it has been 3D Printed! We used nylon 12 to 3D print it with the SLS technic (Selective Laser Sintering).

For the color, we picked a nice Pearl White!

Once I was satisfied with the design and the print tests, I decided to go for it!

We also have created a Ukulele in only one piece, it was printed in a 60 percent scale.

We know you used Shade 3D, but can you tell us more about your modeling technique?

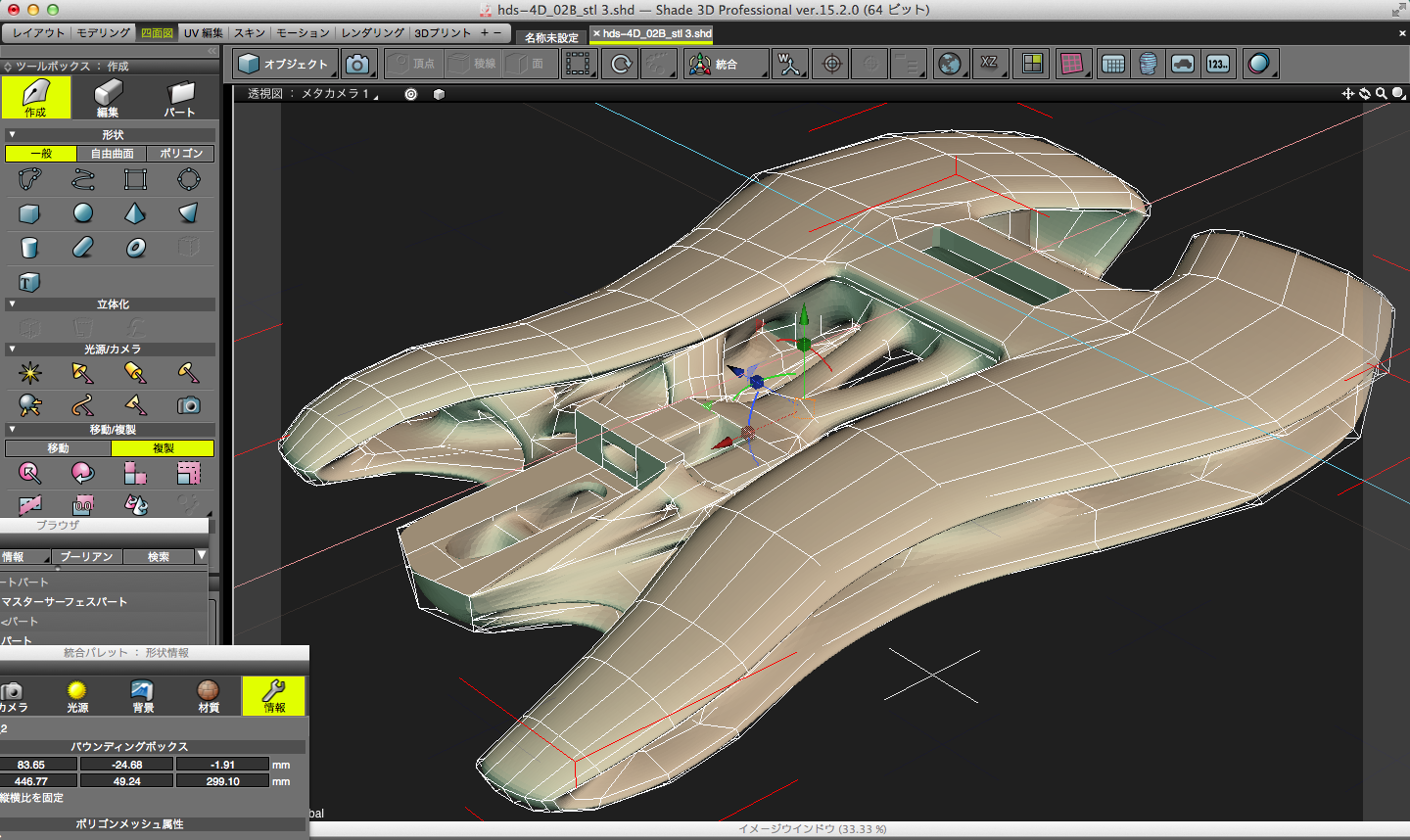

This guitar has been created out of polygons, with the free form modeling technique. I used the new OpenSubdiv function of Shade 3D, which is very convenient as in its latest version, you can manipulate the edges sharpness. It is very intuitive and flexible.

What about the rendering, do you have any tips or personal settings?

Not really, we used 4 point lights and sometimes a spotlight.First, I try to figure out, in my head, how it should look like and then, I start to work on my computer.

What is the main reason you decided to use Shade 3D for this project?

When it comes to product design, I think Shade 3D does a really good job. You can use the free form modeling technique and express your creativity. Even if the guitar is the combination of complex 3D shapes, you can manage to create it with quite few elements.

I think that it would have been very difficult to do that with other CAD software. Curved surfaces are nice, but for this project, we needed to be as accurate as possible.

Is there a special feature that you would like to see in Shade 3D's future?

I have been using Shade 3D for a while, when it comes to industrial products, I like the CAD functions.

I like the fact that interactions are possible between different CAD software, an element of Shade 3D could be exported to another CAD software and vice versa. Mold design needs some SolidWorks knowledge as well.

Is there anything you want to add?

Shade 3D is great for our industrial product designs, it has incorporated many essential tools. Keep up the good work, you got our support!